Unlocking the Future: Automation’s Role in Manufacturing Evolution

Welcome to the cutting-edge of manufacturing, where innovation is the driving force behind productivity and efficiency. In this era of rapid technological advancement, automation stands at the forefront, revolutionizing traditional manufacturing processes and redefining industry standards. Today, we delve into the landscape of automation in manufacturing, exploring the latest trends and technologies that are shaping the future, with insights from NorthAmCon, LLC, a leading expert in industrial 24VDC conveyor and material handling solutions.

LATEST TRENDS AND TECHNOLOGIES:

Artificial Intelligence (AI) Integration

Predictive Maintenance:

- Continuous monitoring of equipment health.

- Identification of potential issues before they cause downtime.

- Reduction of maintenance costs and disruptions to production schedules.

- Data-driven decision-making for continuous improvement.

- AI algorithms process data to detect patterns and anomalies indicative of potential failures. The reliability of 24VDC power ensures continuous and accurate data collection, which is critical for effective predictive maintenance.

Collaborative Robotics (Cobots)

Safe Collaboration:

- Cobots designed to operate alongside human operators.

- Automation of repetitive and physically demanding tasks.

- 24VDC low voltage technology is a safer alternative to traditional AC driven components, ensures seamless integration with cobot control systems, provides stable power for reliable operation, supports advanced sensors for real-time monitoring, and is cost-effective and scalable, optimizing both safety and productivity in collaborative environments.

Increased Flexibility:

- Augmentation of human capabilities, allowing focus on value-added activities.

- Optimization of production processes for greater flexibility and agility.

- Seamless integration of cobots into existing workflows.

- The modular nature of 24VDC power components improves and simplifies the integration of new AI-driven tools with existing infrastructure. Devices such as Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) often run on 24VDC, facilitating seamless data exchange between the AI systems and the operational hardware.

Internet of Things (IoT) Connectivity

Real-time Data Collection:

- IoT-enabled sensors collect data on machine performance and product quality.

- Remote monitoring and management of production processes.

- Proactive decision-making and rapid response to changing conditions.

- Many Internet of Things (IoT) devices are designed to operate on 24VDC. These devices include wireless sensors, gateways, and edge computing units that collect and pre-process data before sending it to AI platforms. The compatibility with 24VDC ensures these devices function efficiently and reliably.

Actionable Insights:

- Data analytics tools analyze vast amounts of data.

- Identification of inefficiencies and optimization opportunities.

- Continuous improvement and operational excellence.

Experience a quieter solution that is easier to install, reduces maintenance and is and more energy efficient.

THE FUTURE OF AUTOMATION IS MANUFACTURING IS BRIMMING WITH POTENTIAL:

In conclusion, as technological advancements continue to unfold, and manufacturers embrace innovation to stay ahead of the curve and remain competitive in today’s market landscape. With NorthAmCon’s expertise and 24VDC solutions, manufacturers can transform towards greater efficiency, productivity, and success.

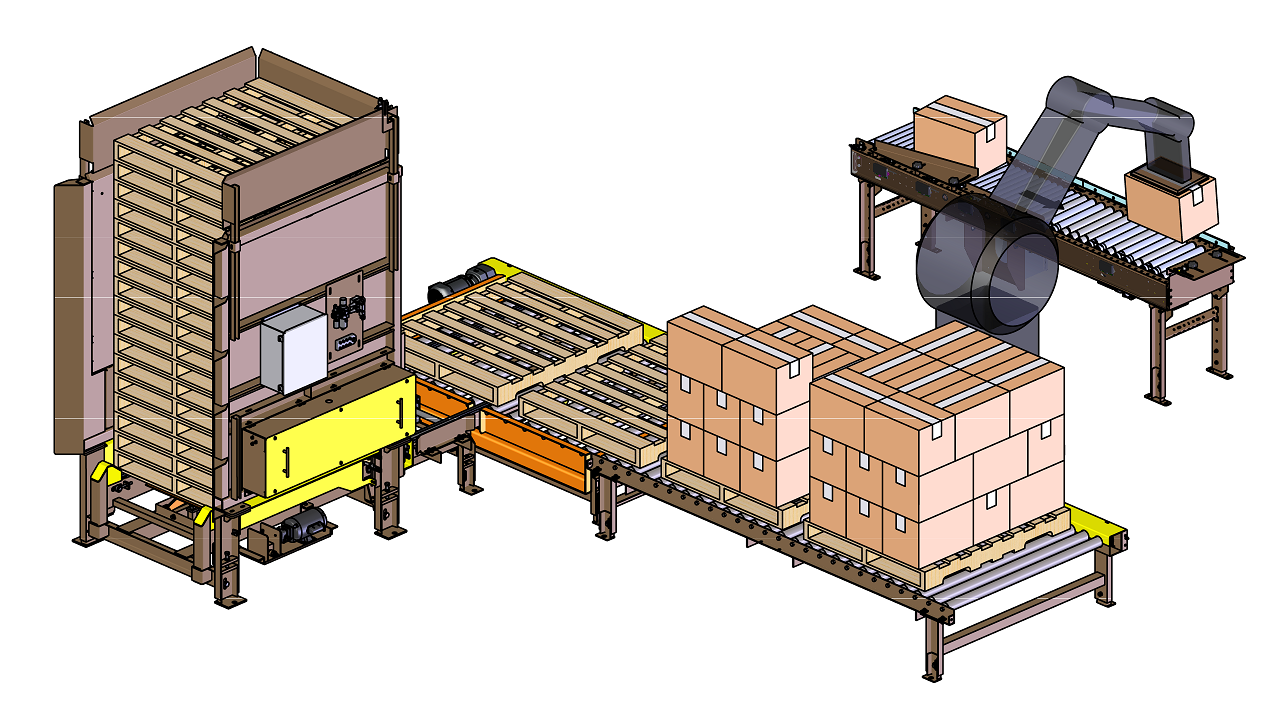

NORTHAMCON, LLC DELIVERING MODERN CONVEYOURS UTILIZING 24V DRIVE TECHNOLOGY:

NorthAmCon, LLC manufactures a full line of standard and build-to-order 24VDC powered conveyors and material handling equipment ideal for robotics & automation, sortation, packaging, and transportation. We specialize in meeting customers needs with the agility and flexibility of a custom fabricator combined with the capabilities of a leading manufacture to deliver solutions that meet the application requirements.

For more information or to request a personalized quote, please contact our dedicated team of experts.

To get in touch, call us at (989)-358-6119