NorthAmCon, LLC offers 24V power driven technologies to meet an endless range of material handling applications.

Known Benefits: Material Handling Equipment powered with 24V low voltage DC power

Known benefits, when compared to other powering choices;

-

Increased energy efficiency.

-

Quieter motors and rollers.

-

Lower maintenance.

-

Air compressor not required.

Energy Efficiency

Run on demand rollers run when needed, and shut down when not in use, extending the life of roller components.

Quieter Motors & Rollers

Low noise created by the 24V DC brushless motors are ideal for packing lines or low decibel environments.

Lower Maintenance

Fewer moving parts, and easily replaceable belts and rollers when required.

Air Not Required

If air available or the compressor is too small to handle pneumatic components, opt for a fully electric system.

Added Benefits: NorthAmCon brings ADDED benefits with a complete range of low voltage, 24V solutions

For powering Material Handling Equipment and accessories;

-

Easy installation.

-

Built to order to fit with existing equipment.

-

Range of powering technologies.

-

Low profile models.

-

More robust and heavy duty.

Easy Installation

Conveyors ship fully assembled, with only a few connections to be made.

Built to Order

Product development based on customer request through responsive engineering so products “fit”.

Multiple Powering Solutions

Exclusive 24V powering technologies available through a single source allows NorthAmCon to offer the most extensive line of low voltage material handling equipment and accessories.

Low Profile

Height profile of the conveyor can be 7″ or lower, depending on the conveyor model.

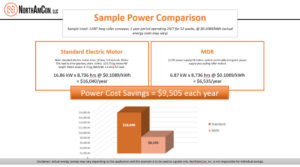

Energy Savings

The energy savings and safety benefits gained with using low voltage equipment.

Click to enlarge chart